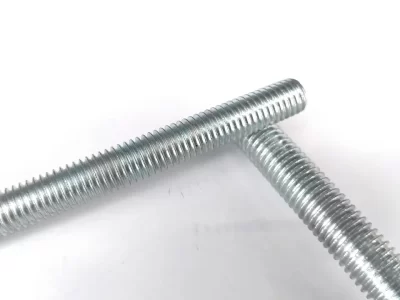

SS 316 Studs are used to mechanically join two or more objects together, either permanently or non-permanently. There are various types of studs and each has its own purpose. Non-Permanent fasteners are manufactured to provide an easy removal and re-use. SS 316 Stainless Steel Studs are usually used in a number of industries and products as they allow for parts to be dissassmbled and re-assembled if required. Non-Permanent studs can be threaded. Type 316 Stainless Steel Studs contains an addition of molybdenum that gives it improved corrosion resistance. This is especially apparent for pitting and crevice corrosion in chloride environments. SS 316 Stud is a mechanical fastener with a threaded shaft. It is usually inserted through two parts, with aligned holes. It is inserted through parts which all have unthreaded holes and 2 nuts are then screwed onto the Stud to offer a clamping force and stop axial movement.

Stainless Steel 316 Studs often rely on axial force causing sufficient friction at the threads to remain in place. This offers elongation of the studs and compression of the elements containing clearance holes. On the other hand some form of locking nut or thread-locking adherent can be used to stop the stud from loosening.

SS 316 Stud has a thread on full-lengths or at both ends. It has three elements if washers are not used. Its length is usually measured end to end or first to first. The length of it is measured parallel to the axis, is the distance from first thread to first thread. A4 Fasteners are commonly known as marine grade stainless fasteners due to its salt water corrosion resistance. It can be found in a number of water-based applications and it is also salt spray resistant. 316 Stainless Steel Studs are especially effective in acidic environments. It is effective in protecting against corrosion caused by acetic, formic, hydrochloric, sulfuric, and tartaric acids, as well as alkaline chlorides and acid sulfates. SS 316 Studs are an austenitic chromium-nickel stainless steel studs that contains between 2% and 3% molybdenum. The molybdenum content improves resistance to pitting in chloride ion solutions, increases corrosion resistance, and strength at high temperatures.

Reviews

There are no reviews yet.